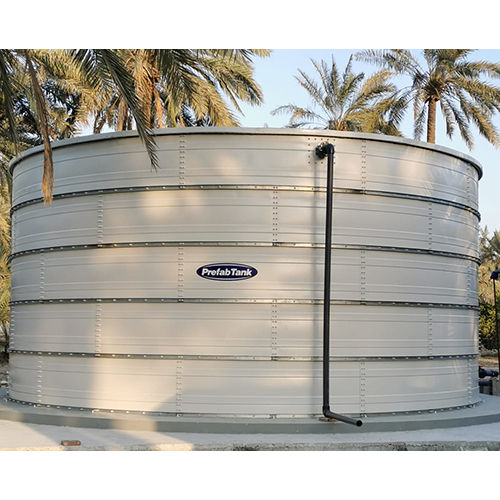

Bolted Tanks

Price 6.0 INR/ Liter

Bolted Tanks Specification

- Grade

- Industrial Grade

- Tolerance

- 1% to Standard Specifications

- Application

- Industrial

- Dimension (L*W*H)

- Customized

- Capacity

- Up to 5000 KL or as per Requirement

- Condition

- NEW

- Processing

- Hot Dipped Galvanized/Coated

- Size

- Customized

- Product Type

- Bolted Tanks

- Color

- Off White

- Leak Proof

- Yes

- Surface Finish

- Corrosion Resistant

- Installation Type

- Bolted / Modular

- Maintenance

- Low

- Usage

- Water / Wastewater / Chemical / Fire Protection Storage

- Material

- Mild Steel / Stainless Steel / Pre-Coated Steel

- Shape

- Cylindrical / Rectangular

Bolted Tanks Trade Information

- Minimum Order Quantity

- 100000 Liters

- Supply Ability

- 10 Liters Per Month

- Delivery Time

- 30 Days

- Main Domestic Market

- All India

About Bolted Tanks

Our Color Coated ZnAL Tanks are engineered for long-lasting water storage solutions. Made from high-tensile steel panels with a durable color-coated finish, these tanks are bolted on-site and lined with a reinforced PVC/EPDM liner to ensure 100% leak-proof performance.

Corrosion Resistant ZnAL coating (55% Al, 43.5% Zn, 1.5% Si) ensures superior life compared to conventional steel.

Modular Design Easy to transport, quick to install, and suitable for all terrains.

Applications Ideal for fire water, raw water, drinking water, rainwater harvesting, STP/ETP water, and industrial process storage.

Capacities Available from 10 KL to 5000 KL and above.

A cost-effective, durable, and eco-friendly solution for bulk liquid storage.

Exceptional Durability and Corrosion Protection

Constructed from mild steel, stainless steel, or pre-coated steel, our bolted tanks are treated with advanced anti-corrosion processes like hot-dip galvanization. This ensures excellent longevity and resistance to harsh environments, making them ideal for challenging industrial applications. The precisely engineered surface finishes provide robust protection and minimize maintenance efforts.

Flexible Customization for Diverse Industrial Needs

Every tank is fully customizable to match your operational requirements. Choose from cylindrical or rectangular designs, various capacities (up to 5000 KL), and adjustable dimensions. Our modular installation allows seamless integration into different sites. Tanks are suitable for water, wastewater, chemical, and fire protection storage, delivering tailored solutions for every industry.

Reliable Leak-Proof and Low-Maintenance Performance

With precision-engineered joints and high-grade materials, our bolted tanks deliver outstanding leak-proof reliability. The modular bolted design supports quick assembly and easy inspection, reducing downtime and simplifying ongoing maintenance. Their efficient build ensures you get a long-lasting storage solution with minimal operational disruption.

FAQs of Bolted Tanks:

Q: How are the bolted tanks installed at industrial sites?

A: Our bolted tanks utilize a modular installation process, allowing rapid assembly on-site by bolting prefabricated panels together. This design is particularly suited for new and retrofit industrial projects, reducing installation time and complexities compared to welded tanks.Q: What materials are available for the construction of these tanks?

A: We offer tanks in Mild Steel, Stainless Steel, and Pre-Coated Steel. Each option is completed with protective finishes such as galvanization or specialized coatings to ensure superior resistance to corrosion in demanding industrial environments.Q: When should I choose a bolted tank over a welded or concrete alternative?

A: Bolted tanks are ideal when you need a quick, modular solution with easy transport and assembly, precise dimensional customization, and exceptional leak-proof performance. They are highly effective for projects requiring future scalability or relocation.Q: Where can these bolted tanks be used?

A: These tanks are designed for a broad range of industrial applications, including water and wastewater storage, chemical containment, and fire protection systems. Their robust construction and modularity make them suitable for various industrial facilities across India.Q: What is the manufacturing process for ensuring corrosion resistance?

A: Each tank component undergoes hot-dip galvanization or is coated with advanced protective layers, creating a strong barrier against rust and environmental agents. This process is critical for maintaining unmatched structural integrity over decades of use.Q: How does the leak-proof feature benefit long-term usage?

A: The leak-proof design prevents loss of stored contents and environmental contamination, ensuring regulatory compliance and operational safety. It also helps minimize maintenance expenses and maximizes the lifespan of the tank.Q: What maintenance is required for these industrial bolted tanks?

A: Thanks to high-quality materials and advanced surface finishes, these tanks require minimal maintenance. Routine visual inspections and occasional cleaning are usually sufficient to sustain optimal performance over time.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Zinc Fused Steel Tanks Category

Industrial Zinc Aluminium Steel Tanks

Price 6 INR / Liter

Minimum Order Quantity : 1 Liter

Application : Industrial

Product Type : Industrial Zinc Fused Steel Tanks

Size : As per requirement

Color : White

Potable Zinc Fused Water Tank

Price 5.50 INR / Liter

Minimum Order Quantity : 5000 Liters

Application : Industrial

Product Type : Potable Zinc Fused Water Tank

Size : As per requirement

Color : White

Industrial Waste Water And Processing Tank

Price 6 INR / Liter

Minimum Order Quantity : 5000 Liters

Application : Industrial

Product Type : Industrial Waste Water And Processing Tank

Size : Customized

Color : Silver

GST : 27AAGCC4375D1ZQ

|

|

COEP ENVIRO SOLUTIONS PVT LTD

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry